High-density polyethylene (HDPE) geomembranes are widely used for applications such as containment, lining, and environmental protection. A critical consideration in choosing the right HDPE geomembrane is its colour—black or white. While black HDPE is more common, white HDPE offers significant benefits, particularly in reducing thermal degradation. This article explores the advantages of white HDPE using data-driven comparisons based on studies conducted by the Atarfil team.

Surface Temperature Differences

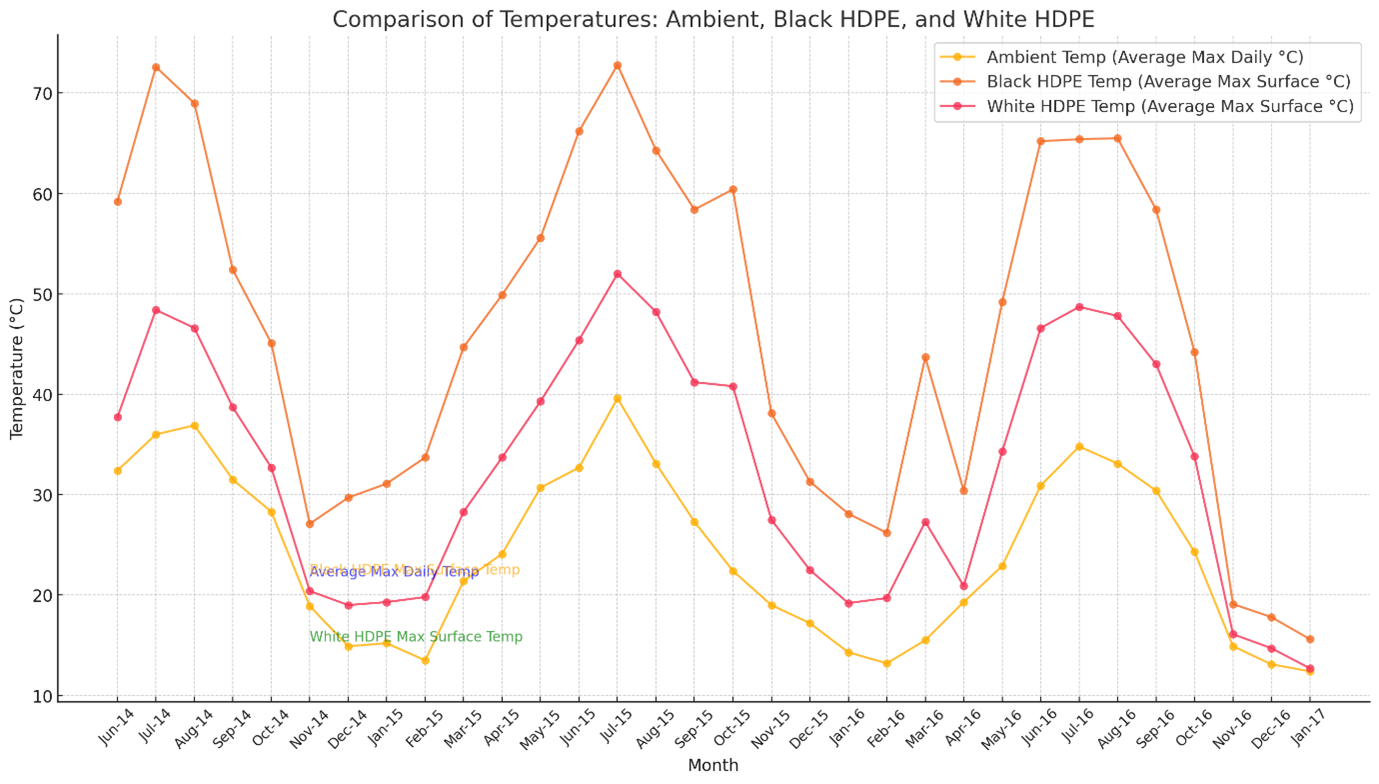

A line chart illustrating these findings emphasises the substantial differences in temperature between black and white HDPE geomembranes, as well as their relationship to ambient temperatures. This chart captures temperature trends over time, clearly showing that:

- Black HDPE consistently exhibits the highest surface temperatures, often exceeding ambient temperatures significantly.

- White HDPE remains cooler, even during peak temperature periods, demonstrating its reflective advantage.

Note on the Line Chart: This chart highlights:

• Ambient temperatures: Represent the average maximum daily temperature for each month. • Black and white HDPE temperatures: Represent the average maximum surface temperatures for each month.

The line chart reinforces that white HDPE provides a much lower thermal load compared to black HDPE, translating directly into reduced thermal degradation and extended durability.

The table below complements the chart by presenting some of the specific monthly temperature data, including the differences between black and white HDPE geomembranes. These details offer a clearer understanding of how reflective properties impact thermal performance.

| Date | Afternoon Temp Average (ºC) | Black HDPE Average Max Temp (ºC) | White HDPE Average Max Temp (ºC) | Temp Difference (Black to White) (ºC) | Temp Difference (%) |

| June 2014 | 22.4 | 59.2 | 37.7 | 21.5 | 36.3% |

| July 2014 | 26.0 | 71.2 | 48.4 | 22.8 | 32.0% |

| August 2014 | 26.1 | 69.0 | 46.6 | 22.4 | 32.5% |

| January 2015 | 6.1 | 31.1 | 19.3 | 11.8 | 37.9% |

| January 2016 | 7.1 | 28.1 | 19.2 | 8.9 | 31.7% |

Data Collection Details

This study’s findings are based on an extensive dataset comprising hundreds of individual data points collected over 2.5 years. These measurements were taken monthly, covering both summer and winter conditions, to provide a comprehensive understanding of temperature variations and their effects on black or white HDPE geomembranes.

Key aspects of the dataset include:

- Coverage: Data was collected across multiple sites in semi-arid and arid climates, including regions of Spain with particularly hot summers.

- Temperature Readings: Average and peak afternoon temperatures were measured to capture the most critical periods of thermal stress.

- Long-Term Trends: Seasonal and annual trends were analysed to assess the durability and performance of the geomembranes under real-world conditions.

In summer months, when average daily temperatures exceed 20°C in semi-arid to arid climates such as Spain, afternoon peak ambient temperatures can often reach 40–45°C or higher. Under these conditions, black HDPE surfaces, which absorb more heat, could reach peak temperatures exceeding 80°C, while white HDPE surfaces, due to their reflective properties, are likely to peak at around 60°C. This highlights the significant benefits of white HDPE in reducing thermal stress.

Benefits of White HDPE

1. Improved Working Conditions

White HDPE’s reflective properties lead to lower surface temperatures, creating a safer and more comfortable environment for installers. Benefits include:

- Easier Installation: Reduced heat on the liner minimises thermal discomfort for installers, enhancing productivity.

- Safer Working Environment: Lower surface temperatures reduce the risk of heat-related injuries during installation.

2. Minimised Wrinkles and Improved Contact

White HDPE’s lower and more consistent sheet temperatures significantly reduce the formation of wrinkles, leading to:

- Better Intimate Contact: Fewer wrinkles ensure better contact between the liner and the subgrade. According to leak rate calculations, improved contact reduces flow rates through any defects, enhancing long-term containment performance.

- Optimised Installation: Reduced wrinkles simplify the installation process and improve overall liner performance.

3. Better Welding Consistency

The reduced variation in sheet temperature ensures:

- Faster Temperature Equilibration: Adjacent sheets reach near equilibrium temperatures more quickly as the temperature of the sheet doesn’t rise as quickly, reducing wait times for welders.

- Stronger Welds: More consistent welding conditions minimise stress in the weld zone, ensuring long-lasting and durable welds.

4. Reduced Thermal Degradation

Black HDPE’s high surface temperatures accelerate thermal degradation and UV-induced aging, reducing the material’s lifespan. White HDPE mitigates these effects by:

- Lowering surface temperatures.

- Slowing oxidation and polymer breakdown.

5. Extended Durability

The slower aging process of white HDPE results in:

- Longer service life.

- Reduced maintenance and replacement costs.

6. Energy Efficiency

In applications requiring temperature-sensitive materials or processes, white HDPE’s lower heat absorption can:

- Reduce cooling needs.

- Enhance operational efficiency by maintaining lower temperatures.

7. Environmental Benefits

White HDPE’s reflective properties can:

- Lower overall site temperatures.

- Reduce the urban heat island effect in large exposed applications.

Applications for White HDPE

White HDPE is particularly advantageous for:

- Exposed Installations: Tailings dams, landfill caps, and water reservoirs where UV exposure is significant.

- High UV Environments: Regions with intense sunlight and high ambient temperatures.

Temporary Covers: Projects where long-term performance under direct sunlight is critical.

Conclusion

The data clearly demonstrates the superior performance of white HDPE geomembranes in managing surface temperatures and reducing thermal degradation. For projects requiring durability, cost-effectiveness, and environmental sustainability, white HDPE provides a compelling solution. These findings are a testament to the extensive research and innovation by the Atarfil team.