High-density polyethylene (HDPE) geomembranes are widely used in containment applications, such as landfills and water ponds, due to their durability and chemical resistance. However, their performance can be severely compromised by degradation processes that affect both the sheet and the welds.

This technical note analyzes degradation mechanisms in detail, highlighting factors contributing to premature failure and proposing improvements in industry practices and testing standards.

1. HDPE Geomembrane Sheets Degradation

A. Exposure to Environmental Factors

HDPE geomembranes are subject to a variety of environmental factors that contribute to their degradation over time. These factors include:

- UV radiation: Prolonged exposure to sunlight can cause photooxidative degradation, which causes the breakdown of the polymer chains in the geomembrane, resulting in reduced tensile strength and increased brittleness.

- Thermal Stress: Temperature fluctuations, particularly in exposed applications, can cause expansion and contraction, generating stresses within the geomembrane. Over time, this can weaken the material and increase the risk of cracking.

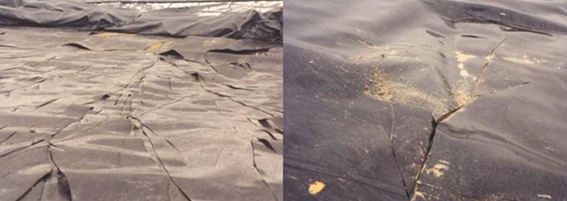

- Physical Stress: The ability of HDPE to resist physical stress is assessed by its Stress Cracking Resistance (SCR). Unfortunately, in many geomembranes, the SCR rarely exceeds 500 hours, which can make them vulnerable to crack initiation and propagation under permanent loads, either from ground-induced stresses or during installation. Although some manufacturers manage to exceed 3,000 hours of SCR, others consider that this is not an essential requirement. However, this position could be influenced by the difficulty of achieving such performance levels.

- Chemical degradation: In many applications, geomembranes are exposed to chemically aggressive environments, which can include extreme pH levels and the presence of heavy metals. Over time, these chemical agents can degrade the geomembrane, affecting its integrity and performance.

B. Importance of Environmental Stress Cracking Resistance (SCR)

The industry has shown a slow evolution in improving Environmental Stress Cracking Resistance (SCR), keeping it at the basic level of 500 hours within the specifications for HDPE geomembranes. This is a significant mistake, as SCR is a critical factor in the geomembrane’s resistance to environmental stresses. However, some doubts have been raised about the validity of the initial SCR value, as some studies suggest that values obtained in pre-exposure conditions may be misleading. After exposure to environmental factors, the degradation of the geomembrane may accelerate considerably, underscoring the need for more advanced testing methods. The introduction of SCR retention testing, similar to Oxidation Induction Time (OIT) retention assessment, could provide a more accurate measure of long-term performance.

HDPE geomembrane sheet with premature failure due to low stress cracking resistance (SCR). Credit: Jonathan Shamrock and Jones & Wagener.

C. Stress and Damage During Installation

Premature ruptures in the geomembrane can also result from improper handling during installation. Examples include:

- Surface Scratches: Poor handling during deployment of the geomembrane by technicians can cause scratches and marks on the surface of the geomembrane, which can immediately reduce its strength by up to 50%.

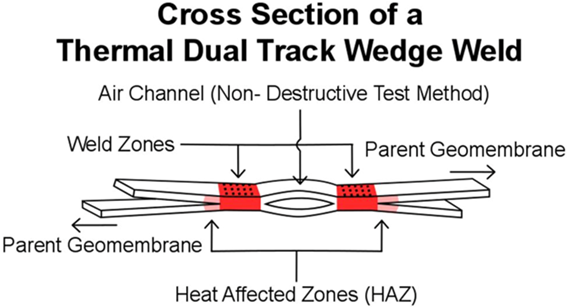

- Overheating during welding: Overheating of the geomembrane during the welding process can affect the zone adjacent to the weld, known as the Heat Affected Zone (HAZ), which can result in excessive loss of essential stabilizers (antioxidants). This weakens the long-term protection of the polymer against the effects of UV, heat and chemical exposure.

2. Degradation of HDPE Welds

A. The Challenge of Heat Affected Zone (HAZ) Degradation

The Heat Affected Zone (HAZ) is a critical area adjacent to welds that is often compromised due to overheating during the welding process. When the HAZ loses the stabilizers designed to protect the geomembrane against environmental factors, it becomes vulnerable to premature rupture. HAZ rupture is a common, but difficult problem to analyze. Existing industry standards, such as GRI GM19, focus on the shear and peel strength of welds without adequately addressing the long-term durability of the welds.

The HAZ areas, indicated by light red zones, are common regions of failure in HDPE geomembrane welds.

B. Proposed Updates to GRI GM19

To improve the durability of welds, it has been proposed to update the GRI GM19 standard by including limitations on weld thickness reduction, ideally restricting it to less than 10%. Thickness reduction is considered a visual indicator correlated with the preservation of Oxidation Induction Time (OIT) values, while maintaining the necessary shear and peel strength of the weld. Further thickness reduction in the weld may be indicative of overheating and significant loss of stabilizers in the Heat Affected Zone (HAZ). However, managing this process on site presents a challenge for geomembrane installation companies due to the lack of effective tools and methods to control weld quality.

C. Increasing OIT Values as an Alternative

In situations where controlling thickness reduction in welds is impractical, an alternative solution would be to increase the Oxidation Induction Time (OIT) values of the geomembrane to compensate for potential overheating losses during welding. Although this approach involves the use of more expensive materials, it reduces the risk of premature weld breakage and reduces reliance on welding technicians.

3. Impact of Temperature Variation During Welding

A. Welding Geomembranes at Different Temperatures

Another common cause of weld rupture is the welding of geomembranes at different temperatures. Temperature variations between the sheets can generate internal stresses within the weld, leading to premature rupture. To mitigate this risk, it is recommended to perform welding and installation at night, when the geomembrane is less affected by solar radiation.

HDPE Panel Temperature Variation Within the Welding Zone

During the day, exposure to sunlight can cause the geomembrane to expand, resulting in wrinkles that interfere with the welding process. By installing at night or using white geomembranes, which reflect solar radiation, the impact of wrinkling can be minimized, improving weld quality and reducing the failure rate.

4. Impacts of Chemical Exposure on HDPE Geomembranes

A. Chemical Durability Ignored

One of the major gaps in current industry practice is the lack of tests reflecting the durability of HDPE geomembranes against chemical exposure. Although we rely heavily on Oxidation Induction Time (OIT) values, which are generally presented in data sheets, these values are primarily designed to illustrate resistance to UV radiation and thermal degradation. However, in many applications, geomembranes are exposed to aggressive chemical environments, including extreme pH levels and/or the presence of heavy metals. These chemicals can degrade the geomembrane over time, and OIT values alone do not provide a clear picture of how the material will perform under such conditions.

B. Role of Stabilizers in Chemical Resistance

HDPE geomembranes need specific stabilizers to resist degradation caused by chemical exposure, in addition to UV radiation and heat. For example:

- Acid or Alkaline Environments: Geomembranes exposed to extreme pH levels require stabilizers that can resist chemical reactions that weaken the polymer structure.

- Heavy Metals: In applications where the geomembrane comes into contact with heavy metals, stabilizers must be formulated to prevent the geomembrane from degrading due to metal-catalyzed oxidation processes.

Currently, most geomembranes are tested to evaluate their performance against UV radiation and temperature, but not against chemical exposure. As a result, two geomembranes that appear identical on their data sheets may behave completely differently in the field, depending on the chemicals to which they are exposed. Without proper chemical resistance testing, it is difficult to accurately estimate the service life of a geomembrane under real-world conditions.

C. The Critical Need for Chemical Resistance Testing

Lack of chemical resistance testing of geomembranes can lead to catastrophic field failures, especially in applications such as landfills, mining and industrial waste containment, where chemical exposure is constant. The difference between a geomembrane that is properly stabilized for its chemical environment and one that is not can mean the difference between a 5-year service life and 500 years. This discrepancy underscores the need for more rigorous testing protocols that consider the specific chemical conditions to which a geomembrane will be exposed during its service life.

For example, a geomembrane exposed to a high sulfuric acid leachate (common in mining applications) requires different stabilizers than a geomembrane used in alkaline conditions, such as in a wastewater treatment plant. However, in the absence of adequate chemical resistance testing, end customers are forced to rely on incomplete data, which does not accurately reflect the long-term performance of the geomembrane in chemically aggressive environments.

D. Moving Toward Comprehensive Testing

To ensure the long-term success of HDPE geomembranes, the industry must expand its testing methods beyond performance against UV radiation and thermal degradation. A more comprehensive approach would involve testing geomembranes against the specific chemical conditions they will encounter in the field. This could include:

- Chemical Resistance Testing: Standardized tests that simulate exposure to various chemical environments, including acids, bases and heavy metals, should be developed and incorporated into geomembrane specifications.

- Customized Stabilization Formulations: Manufacturers should work on creating geomembranes with stabilizers tailored to the specific hazards presented by different chemical environments. This would result in data sheets that reflect not only performance against UV radiation and thermal degradation, but also the chemical durability of the geomembrane.

By focusing on chemical resistance as a key performance indicator, the industry will be able to ensure that HDPE geomembranes will be better able to cope with the diverse and challenging conditions they face in real-world applications.

Conclusion

Degradation of HDPE geomembranes is a complex problem that goes beyond exposure to UV radiation and thermal degradation. While these factors are considered in current testing protocols, chemical exposure represents a significant risk that is often overlooked.

By deepening the understanding of how different stabilizers respond to specific chemical environments and expanding test methods to include chemical resistance testing, the industry will be able to improve the long-term durability and reliability of HDPE geomembranes. This will ultimately result in higher-performing containment systems, a reduced likelihood of ruptures, and greater protection for the environment and public health.